LiPB-32Ah

In order to fully obtain the working performance of the power battery, each test needs to be tested separately at multiple different temperatures and different aging conditions to realize the full-life efficient management of the full-climate power battery.

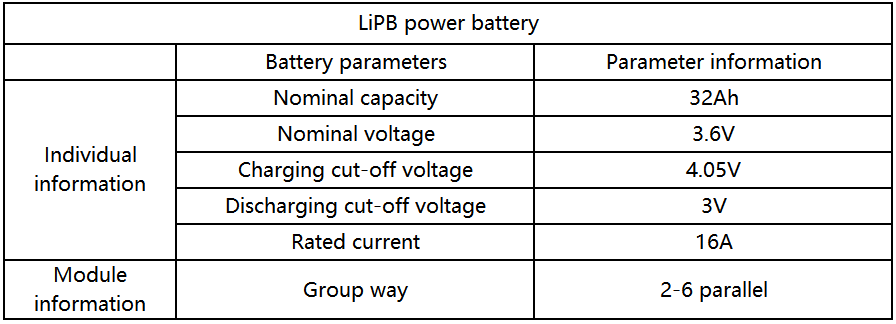

Data completion time: individual: 2014-1-31, module: 2013-11-30

1.Basic battery parameters

2.Test process

2.Test process

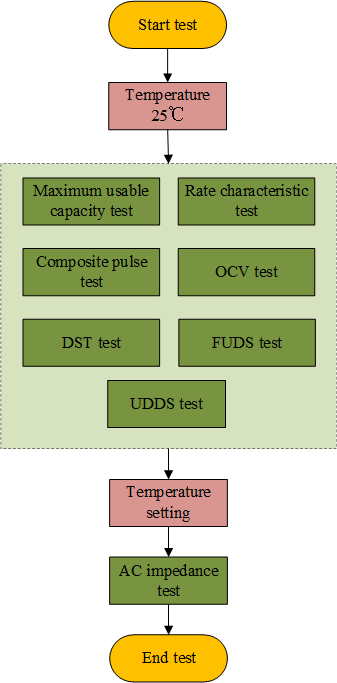

Battery individual: Arbin BT2000-01 is used as a charging and discharging device for experiments. The battery individual test flow chart is shown in the figure below.

Figure 1 Battery individual test process

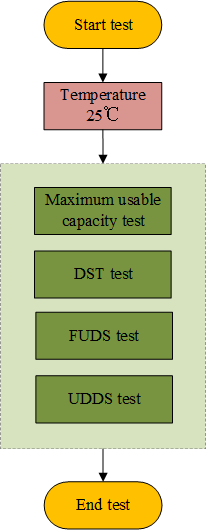

Battery pack: Arbin is used as a charging and discharging device for experiments. The battery pack test process is shown in the figure below.

Figure 2 Battery pack test process

3.Introduction to the data set

Battery individual: The maximum usable capacity test/rate characteristic test/composite pulse test/OCV test/AC impedance test/DST test/FUDS test/UDDS test. Except the electrochemical impedance spectroscopy test, other experiments are performed at 25°C.

Battery pack: The capacity/working condition experiment was carried out.

4.Battery characteristic curve

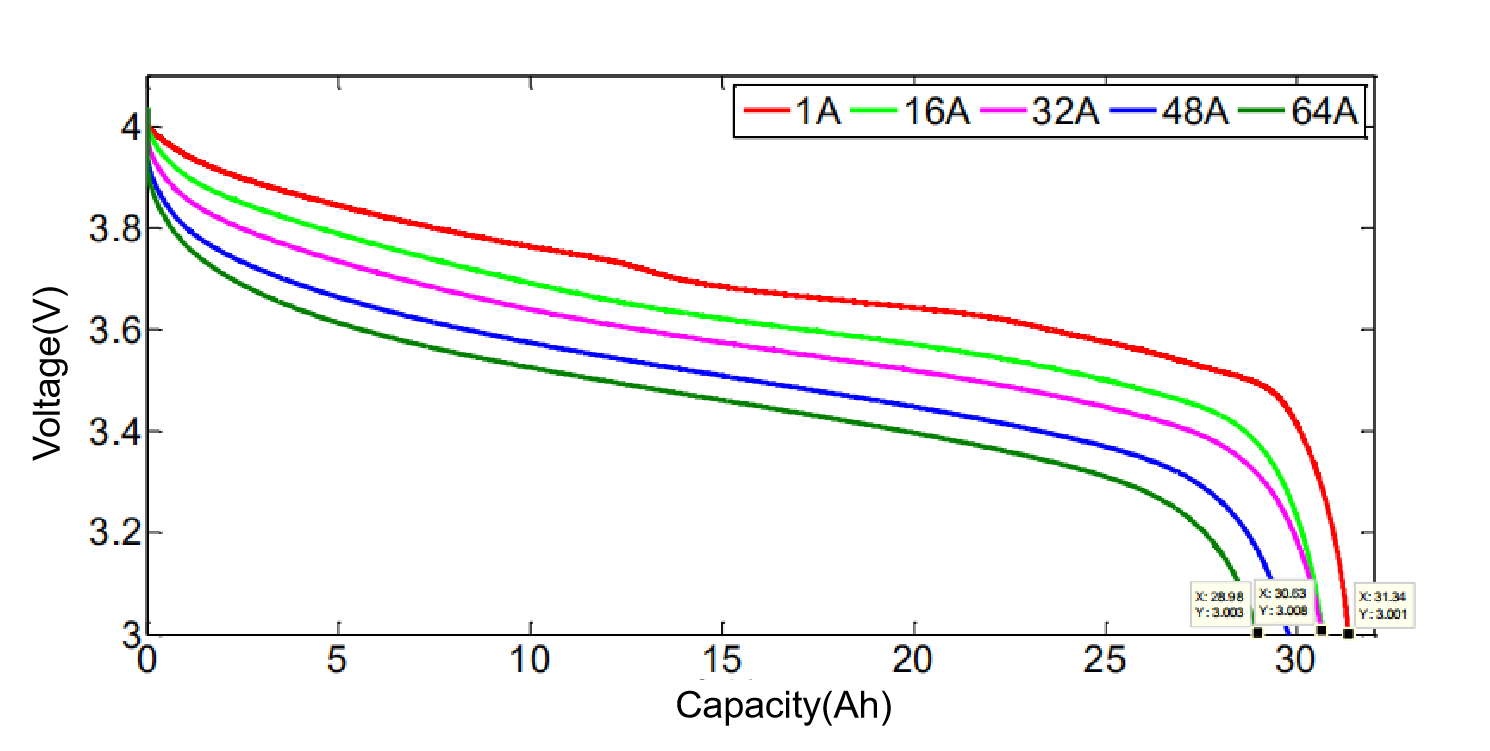

Figure 3 Constant current discharge curve of LiPB under different currents

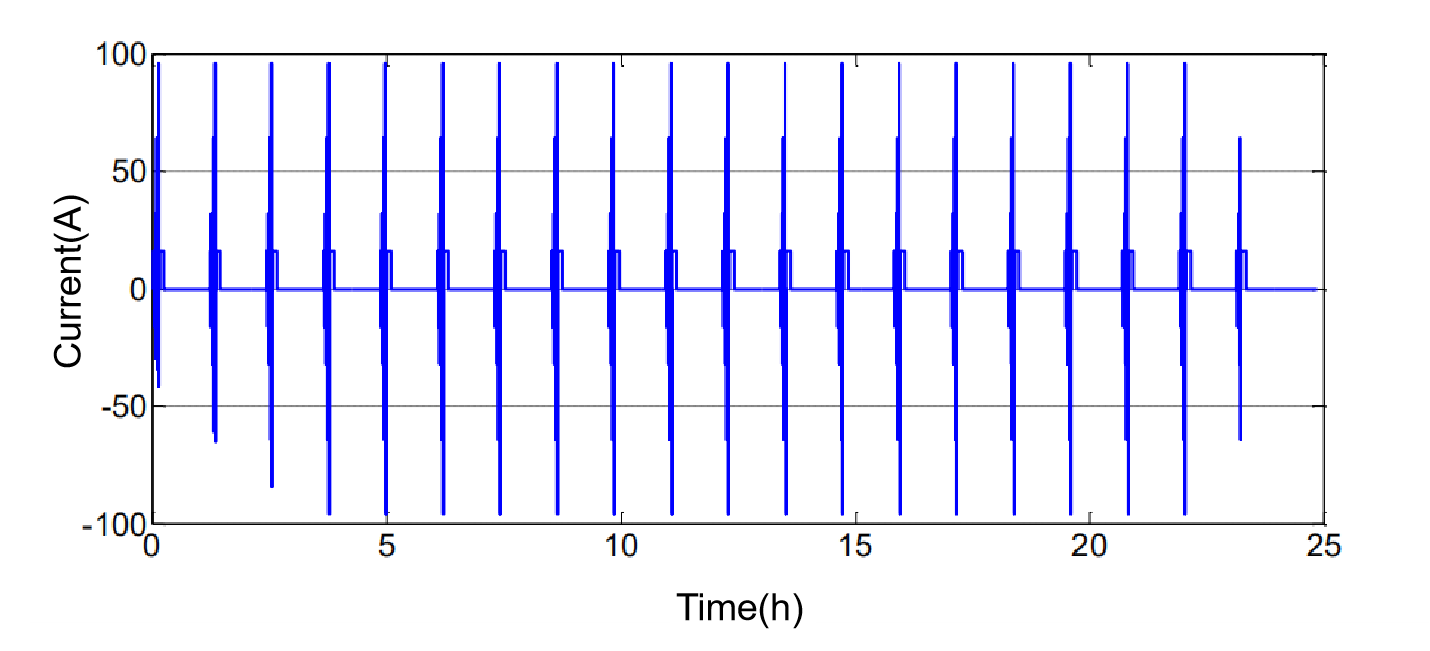

Figure 4 Lithium-ion battery individual composite pulse test

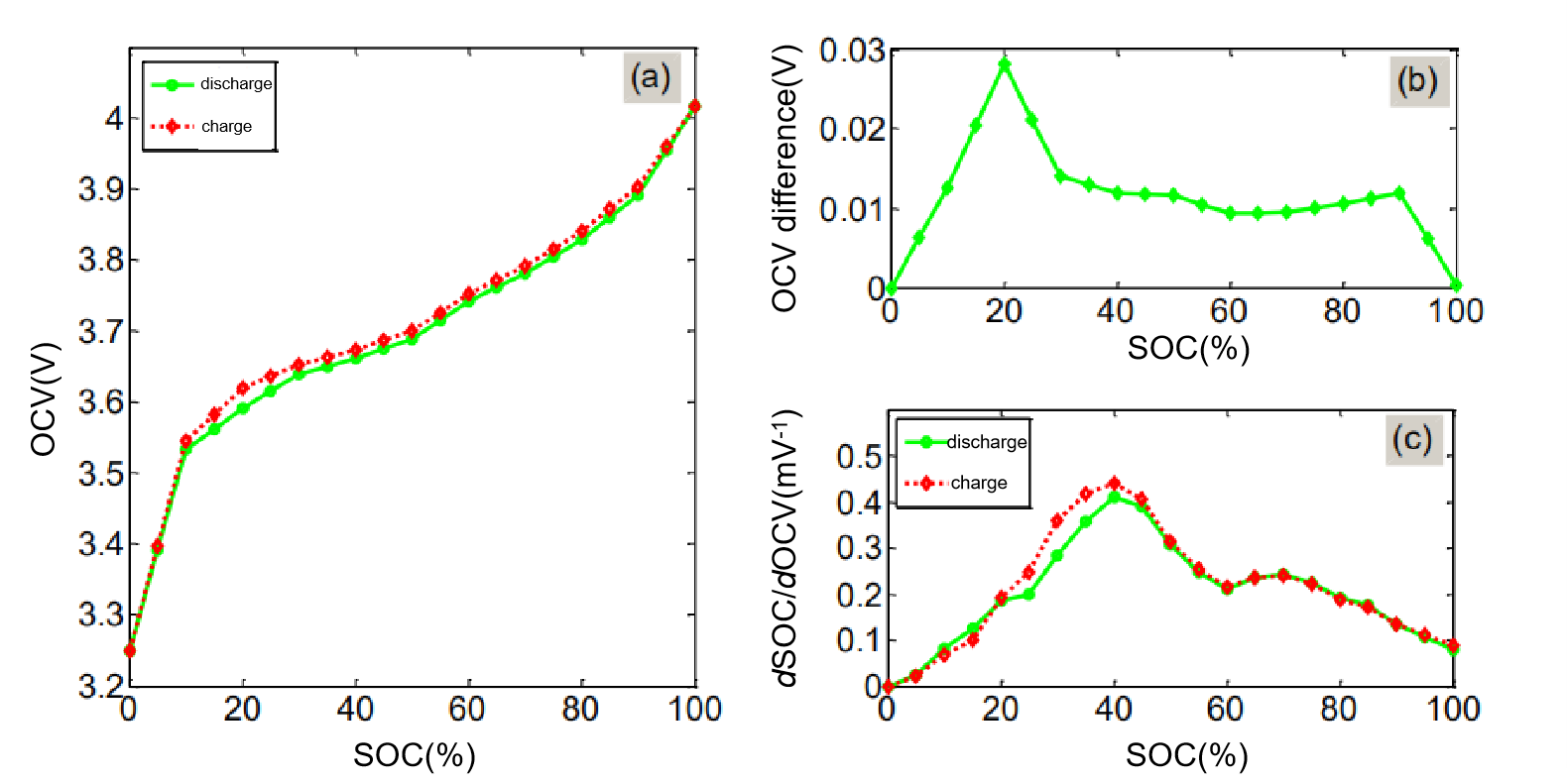

Figure 5 LiPB OCV curve of power battery and its related characteristics: (a) the corresponding relationship between OCV and SOC; (b) the difference of OCV in different charging and discharging states; (c) the change of SOC corresponding to each millivolt of OCV

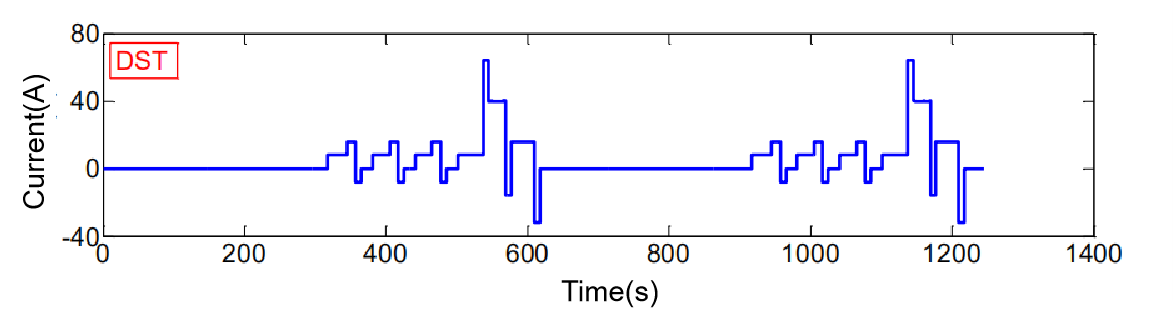

Figure 6 DST test data

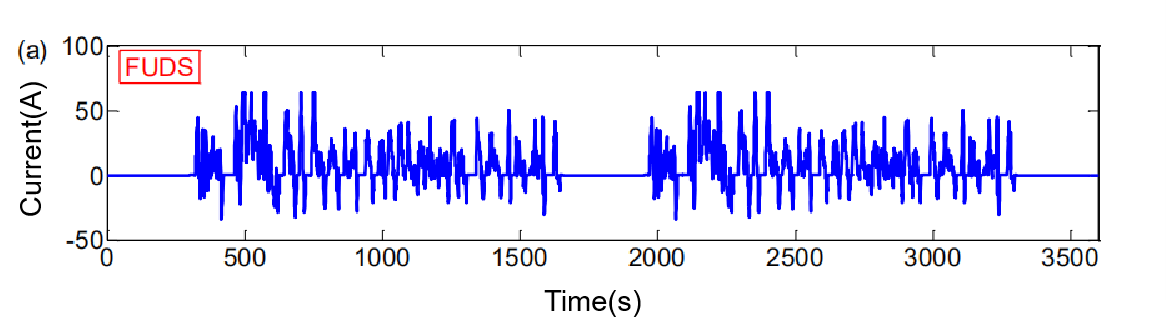

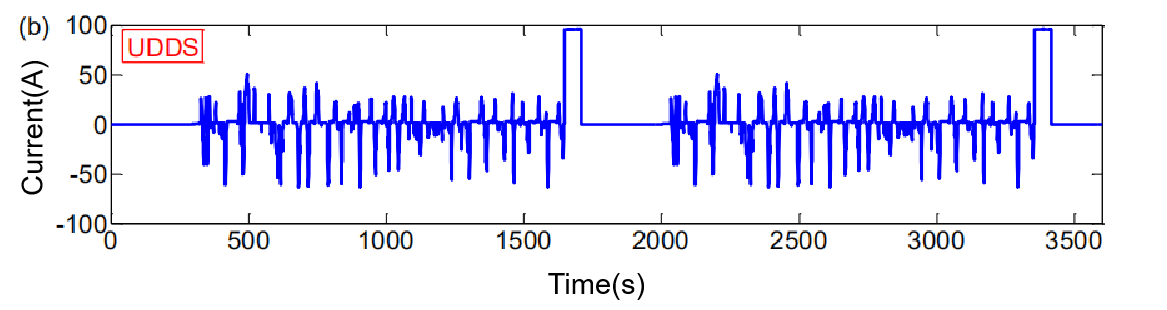

Figure 6 Test data of dynamic working conditions: (a) FUDS working condition; (b) UDDS working condition

5、Related papers

[1] F. Sun; R. Xiong* and H. He, “Estimation of state-of-charge and state-of-power capability of lithium-ion battery considering varying health conditions”, J. Power Sources, vol.259, pp.166–176, Aug 2014. (Download)

[2] R. Xiong*, F. Sun, X. Gong and C. Gao, “A data-driven based adaptive state of charge estimator of lithium-ion polymer battery used in electric vehicles”, Applied Energy, vol. 113, pp. 1421–1433, Jan 2014. (Download)

[3] R. Xiong*, F. Sun, Z. Chen and H. He, “A data-driven multi-scale extended Kalman filtering based parameter and state estimation approach of lithium-ion polymer battery in electric vehicles”, Applied Energy, vol. 113, pp. 463-476, Jan 2014. (Download)

[4] R. Xiong, X. Gong and C. Mi*, “A robust state-of-charge estimator for multiple types of lithium-ion batteries using adaptive extended Kalman filter”, Journal of Power Sources, vol. 243, pp. 805–816, Dec 2013. (Download)

[5] R. Xiong*, F. Sun, X. Gong and H. He, “Adaptive state of charge estimator for lithium-ion cells series battery pack in electric vehicles”, Journal of Power Sources, vol. 242, pp. 699–713, Nov 2013. (Download)