SOH estimation

1. Classification of SOH estimation methods

The storage capacity and fast charge discharge capacity of power battery will decrease with aging, and SOH is the quantitative index to evaluate the aging degree of power battery. The accurate estimation of power battery SOC depends on the accurate value of SOH. The SOC estimation based on foreseeing SOH is not practical and can only provide a preliminary reference for SOC estimation methods.

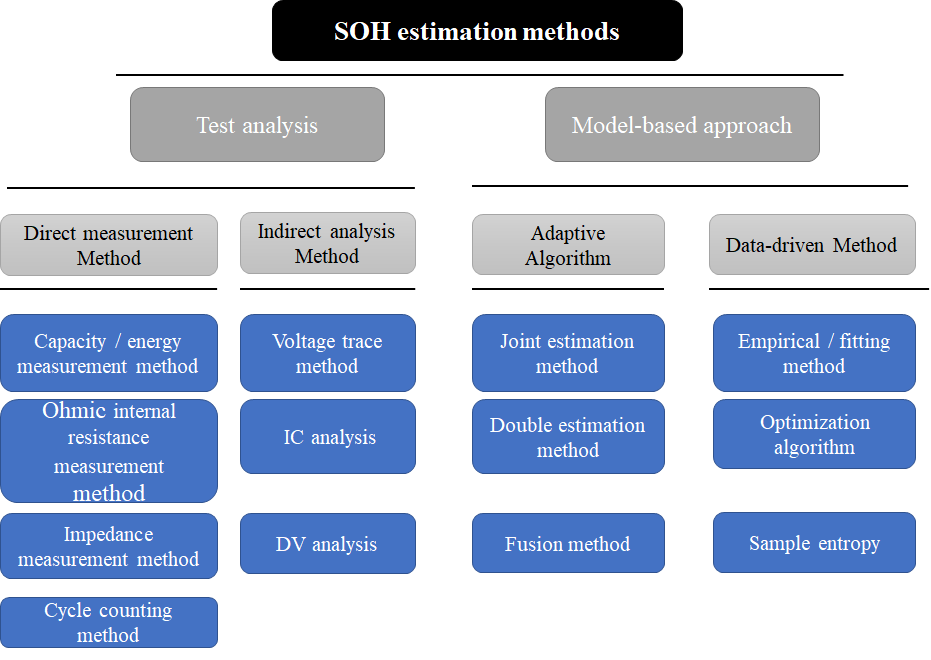

The SOH of power battery is closely related to the aging process of power battery, and the most intuitive performance of aging is the decrease of energy released by power battery and the decrease of power level. The internal reflection is the decrease of power battery capacity and the increase of internal resistance. Therefore, the capacity and internal resistance of power battery are often used as the evaluation index of SOH. Generally speaking, the SOH of new power battery is set at 100%. For pure electric vehicles with power battery capacity as the main demand, it can be considered that the power battery can not meet the normal demand when the power battery capacity reaches 80% of the initial capacity; for hybrid electric vehicles with power battery power as the main demand, it often uses twice of the initial internal resistance value as the power battery termination use conditions. SOH estimation methods can be divided into two categories, namely experimental analysis method and model-based method, as shown in Figure 1. The former refers to the relatively direct acquisition of some characteristic parameters that can reflect the decline of power battery by analyzing the collected experimental data of power battery, such as current, voltage and temperature, so as to realize the calibration of power battery SOH. According to the different parameters of power battery, it can be divided into direct measurement method and indirect analysis method. The latter requires the power battery model to calibrate the selected power battery SOH. According to the different estimation algorithms, it can be divided into adaptive algorithm and data-driven method.

Figure 1 Classification of power battery SOH estimation methods

Direct measurement Method

The direct measurement method is to evaluate the SOH of power battery by directly measuring some characteristic parameters of power battery, mainly including capacity / energy measurement method, ohmic internal resistance measurement method, impedance measurement method and cycle counting method. ① Capacity / energy measurement method refers to the accurate and direct measurement of power battery capacity or energy to determine the SOH of power battery. Obviously, the accurate measurement of capacity and energy needs at least two preconditions: one is to ensure the integrity of the charging and discharging process, the other is to ensure that the acquisition accuracy is high enough, which means that this method can only be used in the laboratory or other relatively stable conditions. For real vehicle environment, online capacity identification method is often needed. ② Ohmic internal resistance measurement method is to evaluate the SOH of power battery by measuring the ohmic internal resistance of power battery in real time. The calculation method is shown in formula (1), that is, the ratio of voltage change and current change of power battery. Compared with the capacity of power battery, ohmic internal resistance is easier to measure. Sudden braking or acceleration in the process of real vehicle will cause large changes in the current and voltage of power battery. However, in addition to the influence of SOH and temperature of power battery, the ohmic internal resistance also changes with the change of SOC, and it is significantly affected by the sampling interval of current and voltage, that is, the smaller the sampling interval is, the closer it is to the true value of ohmic internal resistance. At the same time, when calculating ohmic internal resistance, the minimum absolute value of IL should be limited, otherwise the result will fluctuate sharply. ③ The impedance measurement method needs electrochemical workstation or other similar AC excitation equipment to measure the EIS of power battery.

| (1) |

Indirect analysis Method

Indirect analysis method is a typical multi-step derivation method, which does not directly calculate the capacity or internal resistance of power battery, but calibrates the SOH of power battery by designing or measuring some process parameters that can reflect the decline of capacity or internal resistance of power battery. These process parameters are usually called health factors, including impedance of SEI, power battery capacity-OCV-SOC response surface, voltage response trajectory or constant voltage charging time, IC (incremental capacity) curve or DV (differential voltage) curve, ultrasonic response characteristics, etc. Of course, two or more health factors can be selected to evaluate the SOH of power battery. ① The voltage response of the power battery directly reflects the internal response characteristics of the power battery, so the voltage response trajectory under specific SOC, temperature and current input can be analyzed based on the control variable method to complete the SOH calibration. This method is called voltage response trajectory method. At the same time, considering the complex and changeable discharge conditions of power battery, the relatively stable charging process is often used as the analysis object. At present, the most common charging method is constant current and constant voltage charging. For the power battery with the same material, the overall charging time of this charging method basically remains unchanged, while the charging time of CV stage will increase significantly with the aging of the power battery. Therefore, if the charging curve of the complete CV stage of the power battery can be obtained, the SOH of the power battery can be calculated accurately. ② Capacity increment method (ICA: IC analysis) and differential voltage method (DVA: DV analysis) respectively use IC curve and DV curve to analyze the degradation process and aging mechanism of power battery, and then achieve SOH calibration. IC curve and DV curve can be obtained by constant current charge discharge data transformation. The former describes the relationship of dQ/dV-V, while the latter describes the relationship of dV/dQ-Q.

Adaptive Algorithm

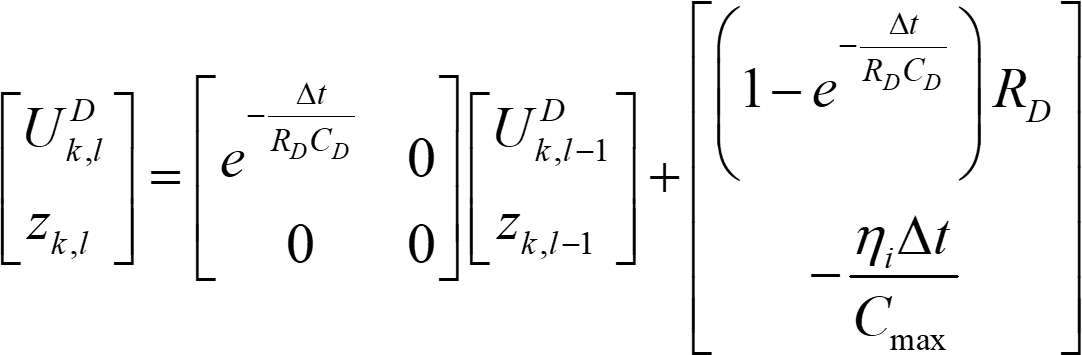

The adaptive algorithm usually needs the help of electrochemical model or equivalent circuit model, which can complete the calibration of SOH by identifying the model parameters. This kind of method is characterized by closed-loop control and feedback to realize the adaptive adjustment of the estimation results with the power battery voltage, including joint estimation method, collaborative estimation method, and fusion estimation method. ① The joint estimation method needs to estimate the model parameters and SOC of power battery on line at the same time, so the adaptive algorithm generally includes two or more filters or observers, in which the model parameters mainly include internal resistance, impedance, OCV and so on. Since SOC of power battery is closely related to capacity, the capacity of power battery can be determined according to the estimated value of SOC after obtaining relatively accurate SOC value, and then the calibration of power battery SOH can be completed. ② The collaborative estimation method also needs to realize the on-line estimation of power battery model parameters and SOC at the same time, but the model parameters here add a power battery capacity item compared with ①, that is, the simultaneous estimation of power battery capacity and SOC is directly completed. From the perspective of general algorithm framework, the difference between collaborative estimation method and joint estimation method is mainly reflected in two aspects: (a) for the two kinds of estimation algorithms, the usage mode of innovation (output prediction voltage error) sequence is different. Two estimators share the same innovation sequence. But in the joint estimation method, the voltage errors of the two estimators are uncorrelated; (b) the relationship between parameter estimation and state estimation is different. In the collaborative estimation method, the state estimation and parameter estimation will interact with each other, but the joint estimation method has no obvious interaction effect.

Data-driven Method

The data-driven SOH estimation method does not rely on an accurate mathematical model to describe the aging principle and evolution process of power battery, but only relies on historical aging data, that is, the key aging information of historical data points is extracted through a specific learning algorithm. ① Empirical / fitting method is to predict the life of power battery by using existing aging data without detailed understanding of the structure and material characteristics of power battery. Polynomial, exponential, power-law, logarithm and trigonometric functions are commonly used empirical models and fitting models, which usually have less calculation and faster calculation speed. For example, Arrhenius kinetic equation is not only very concise, but also accurately describes the temperature dependence of chemical reaction rate, so it is often used to simulate the changes of diffusion coefficient, creep rate and other thermal processes caused by temperature. Arrhenius kinetic equation can also be used to describe the temperature dependent aging rate of power battery. ② Sample entropy can be used to evaluate the predictability of time series and quantify the regularity of data series. Therefore, sample entropy can be used to analyze the discharge voltage data of power battery and indicate the SOH of power battery.

2. Power battery available capacity estimation method based on SOC estimation

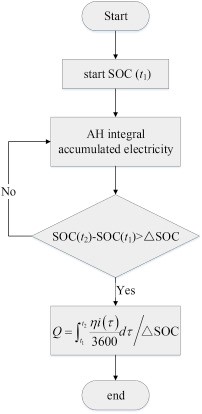

The flow of the algorithm is shown in Figure 2, and the specific implementation process is as follows:

Figure 2 Problem description of power battery available capacity estimation method based on SOC estimation

① Real time power battery data acquisition, including current, voltage, temperature, etc., the collected data is sent to the controller for real-time calculation of the algorithm; ② Model parameter identification based on online measurement data drive. Based on the collected data, RI, RD and CD of Thevenin model are calculated, and the results are used for subsequent SOC estimation; ③ SOC estimation. Based on the collected data and online identification results, the SOC estimation algorithm based on AEKF is used to achieve the accurate estimation of SOC, and the calculation results are used for the subsequent available capacity estimation; ④ Available capacity estimation. After the SOC estimation of power battery is obtained, whether the above three boundary conditions meet the requirements should be judged. If so, the available capacity can be calculated directly; otherwise, the available capacity will not be updated.

3. Main Results

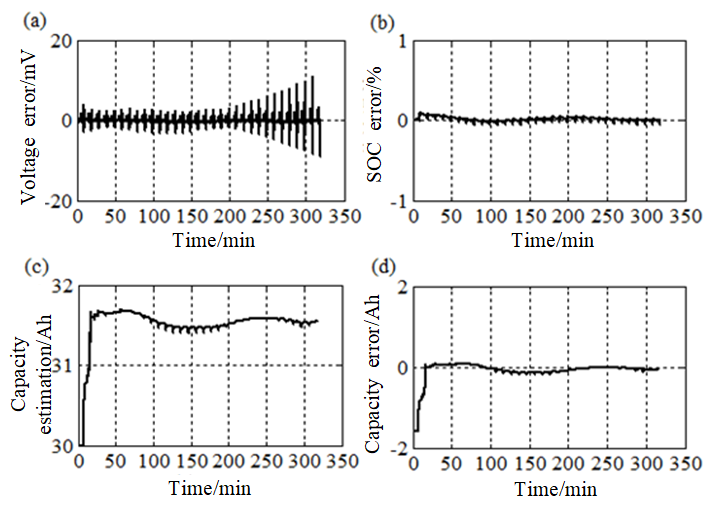

In this section, DST data of power battery 2 is used to evaluate the accuracy of the joint estimation method of power battery SOC and available capacity. LS is set to 360s. Figure 3 shows the estimated results using the power battery 2-cell 01 data under the precise SOC initial value. It should be noted that the maximum available capacity of power battery 2-cell 01 is 31.6 A·h, and the initial value of available capacity in this algorithm is set to 30 A·h. Since the available capacity estimation is started after 360s, the maximum available capacity in 0 ~ 360s is the initial value of 30 A·h by default.

Figure 3 Estimation of available capacity of power battery based on SOC estimation (accurate SOC initial value): (a) voltage estimation error; (b) SOC estimation error; (c) available capacity estimation result; (d) available capacity estimation error

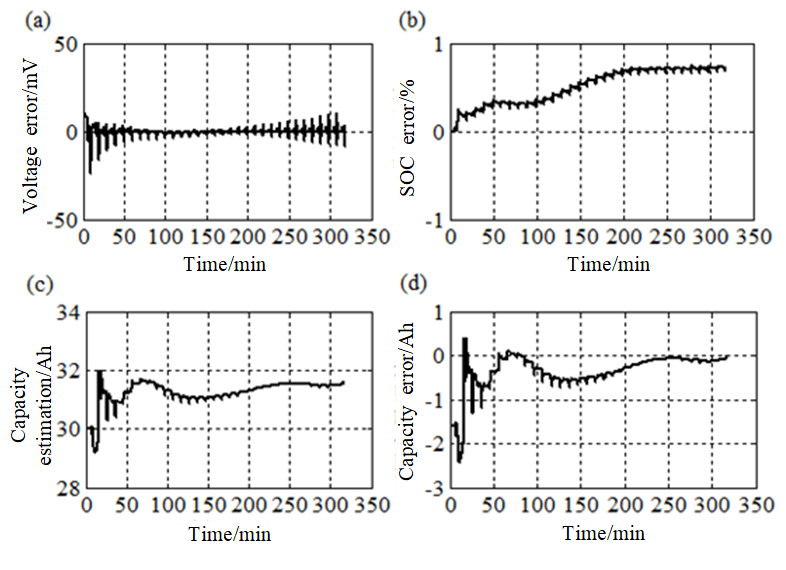

It can be seen that the power battery voltage estimation error is less than 15 mV, SOC estimation error is less than 1%, and the maximum available capacity estimation error is less than 2 A·h. At the moment when the available capacity estimator is turned on, the capacity estimation value will jump, but the setting of convergence coefficient will prolong the holding time of the initial capacity, so as to avoid the disturbance of excessive available capacity estimation value affecting the stability of SOC estimation value. Therefore, the power battery voltage estimation accuracy, SOC estimation accuracy and maximum available capacity estimation accuracy based on accurate SOC initial value are ideal. However, the accurate estimation method does not need to rely on the accurate initial value of the state observer. Figure 4 shows the estimation result based on 60% SOC initial value, that is, there is 40% SOC initial error.

Figure 4 Estimation of available capacity of power battery based on SOC estimation (initial SOC value is 60%): (a) voltage estimation error; (b) SOC estimation error; (c) available capacity estimation result; (d) available capacity estimation error

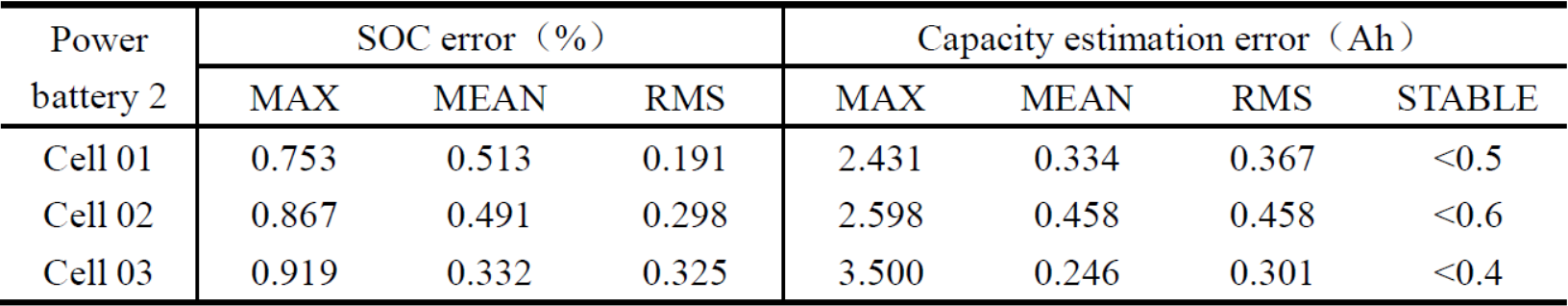

It can be seen that the algorithm is not sensitive to the imprecise SOC and available capacity initial value. The initial value error only affects the number of iterations that need to achieve stable estimation. The estimation accuracy is higher after 50 minutes. At this time, the maximum voltage prediction error is less than 20 mV, the maximum SOC estimation error is less than 1%, and the maximum available capacity estimation error is less than 0.6 A·h. In order to systematically evaluate the accuracy of SOC and available capacity estimation methods based on SOC estimation, the statistical analysis results of SOC and available capacity estimation are listed in Table 1. Since LS is 360s, the absolute value of estimation error after 480s convergence calculation is selected for analysis, and the initial value of SOC is 60%.

Table 1 Estimated error of power battery SOC and available capacity based on SOC estimation value (initial SOC is 60%, 480s)

It can be seen that the estimation error of SOC of power battery is less than 1%, and the estimation error of usable capacity after stabilization is less than 0.6 A·h. Considering that the rated capacity of power battery is 32 A·h, the estimation error of available capacity is less than 2% and less than the set convergence coefficient.

4. References

[1] R. Xiong. Core Algorithms of Battery Management System. Beijing:China Machine Press,2018. (Chinese) (Chapter Four)

[2] R. Xiong*, L. Li and J. Tian, “Towards a smarter battery management system: A critical review on battery state of health monitoring methods”, Journal of Power Sources, vol.405, pp.18-29, Nov 2018. (Download)

[3] R. Xiong*, Q.Q Yu*, LY Wang, C Lin, “A novel method to obtain the open circuit voltage for the state of charge of lithium-ion batteries in electric vehicles by using H infinity filter”, Applied Energy, vol. 207, pp. 341-348, Dec 2017. (Download)

[4] R. Xiong*, F. Sun, Z. Chen and H. He, “A data-driven multi-scale extended Kalman filtering based parameter and state estimation approach of lithium-ion polymer battery in electric vehicles”, Applied Energy, vol. 113, pp. 463-476, Jan 2014. (Download)

[5] R. Xiong*, F. Sun, H. He and T. Nguyen, “A data-driven adaptive state of charge and power capability joint estimator of lithium-ion polymer battery used in electric vehicles”, Energy, vol. 63, pp. 295–308, Dec 2013. (Download)

[6] R. Xiong*, F. Sun, X. Gong and H. He, “Adaptive state of charge estimator for lithium-ion cells series battery pack in electric vehicles”, Journal of Power Sources, vol. 242, pp. 699–713, Nov 2013. (Download)

[7] R. Xiong, X. Gong and C. Mi*, “A robust state-of-charge estimator for multiple types of lithium-ion batteries using adaptive extended Kalman filter”, Journal of Power Sources, vol. 243, pp. 805–816, Dec 2013. (Download)

[8] R. Xiong, H. He*, F. Sun and K. Zhao, “Evaluation on State of Charge Estimation of Batteries with Adaptive Extended Kalman Filter by Experiment Approach”, IEEE Transactions on Vehicular Technology, Vol. 62, no.1, pp. 108–117, Jan 2013. (Download)

[9] R. Xiong*, H. He; F. Sun and K. Zhao, “Online Estimation of Peak Power Capability of Li-Ion Batteries in Electric Vehicles by a Hardware-in-Loop Approach”, Energies, vol. 5, no. 5, pp. 1455-1469, May 2012. (Download)

[10] H. Mu, R. Xiong*, H. Zheng, Y. Chang and Z. Chen, “A novel fractional order model-based state-of-charge estimation method for lithium-ion battery”, Applied Energy, vol. 207, pp. 379-388, Dec 2017. (Download)

5. Available Resources

(1) SOH estimation algorithm information: click to download (![]() PDF watermark textbook)

PDF watermark textbook)